Computer Numerical Control (CNC) is a type of machining, has revolutionized engineering and manufacturing in the last few decades. CNC machining, which combines modern technology with traditional manufacturing methods, has become an essential method to produce precision products and components to suit a broad range of industries. This article will explore the mechanics and benefits and numerous applications of CNC cutting to emphasize the impact it has on the modern engineering.

The Mechanics of CNC Machining

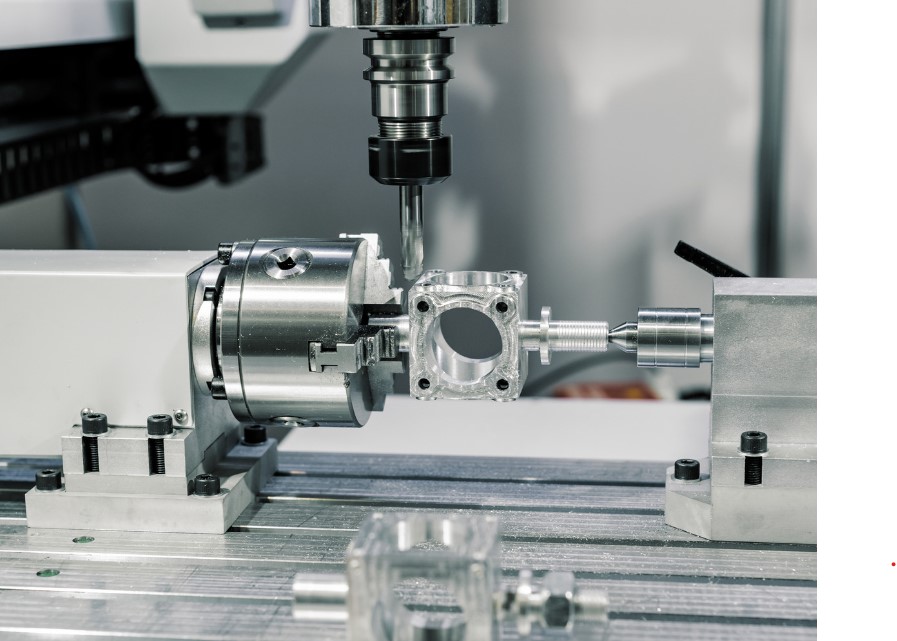

CNC machine, also known as subtractive manufacturing is a method which takes material away to create a desired shape from a solid piece of metal. The software that computers use to control the machine’s movement is pre-programmed. The codes used by CNC machines may differ based on the machine type and complexity of the component produced. The basic concept remains the identical: a high speed cutter is meticulously shaves material for the final product.

The precision of CNC machine is among its most significant advantages. Digitalization allows for highly precise and constant production. This helps reduce human error, while ensuring consistency between batches. This level of precision is crucial in fields where even smallest deviations can have significant impacts, such as aerospace, medical devices manufacturing, and automotive.

Digital computers play a crucial role in CNC machine operations

CNC Machining is a highly precise and efficient process that is based on the digital technology. CNC machines are operated using specialized software that automates the entire manufacturing process. This software converts computer-aided design (CAD) models into a series of precise instructions, which the CNC machine then follows to create the part. The instructions define every aspect of the process, from the direction and speed of the tool used to cut, as well as the length and angle of each cut.

In industrial facilities with larger scales computers are often integrated directly into the CNC machines, which allows for seamless communication and control. This integration allows constant adjustments in real time and monitors that ensures optimal performance and minimize time to repair. Automation of CNC machine tools also allow for continuous operation, dramatically increasing productivity and reducing time to market.

CNC Machining Benefits

CNC machining is a highly efficient method for manufacturing. Its capability to make intricate and complex parts with high precision is one of the main advantages. CNC machining is accurate and eliminates the need for manual adjustments or Rework. This helps reduce loss and enhances efficiency. CNC machines also operate continuously and are ideal for production runs that are large.

CNC milling has another benefit it’s the flexibility. Through the modification of the program, the same machine can create many different components. CNC machining can be used for both mass production and prototyping, thanks to its adaptability.

The automated process of CNC machines also increases security in the workplace. Injuries and accidents are less likely when manual intervention is not necessary. The consistency of quality in CNC manufactured parts enhances the reliability and performance of products, which leads to the satisfaction of customers.

Industries benefiting from CNC Machining Services

CNC machineries are utilized in a variety of industries. Each benefiting from its precision, efficiency and adaptability. CNC machines are utilized in the aerospace industry to make vital components that must satisfy the strict requirements for safety and performance. The medical device industry relies on CNC machine machining to make of surgical instruments that are complex and implants, where precision is essential.

CNC machining can be used to create engine components, transmissions, intricate interior and exterior elements, and even intricate exterior and interior designs in the automobile industry. Electronics industry also benefit from CNC processing, which allows it to produce small, intricate parts for consumer electronic devices and communication equipment. Art and jewelry industries make use of CNC technology to create intricate designs and custom pieces.

The Future of CNC Machining

CNC machining is expected to expand as technology improves. Multi-axis processing and additive manufacturing integration are expected to continue to push CNC technology’s limits. In addition, machine learning and AI will improve CNC processing efficiency.

CNC machining is a powerful instrument that has had a profound impact on engineering and manufacturing in the current era. It offers unparalleled quality, flexibility and effectiveness. The ability to create complex components with high accuracy makes it a valuable tool for all industries. CNC machining, as the technology develops will remain an integral part of manufacturing’s future.