Wire cleaners and wire rope lubricators are indispensable in the world of repair and maintenance, where precision is key. These devices are essential for ensuring a smooth and efficient operation of the cable as well as long-lasting life in various industries. Wire cleaners and rope lubricators are essential for maintaining cables. In this piece, we look at their uses, benefits and the positive effects they have on the overall effectiveness.

Understanding Wire Rope Lubricants:

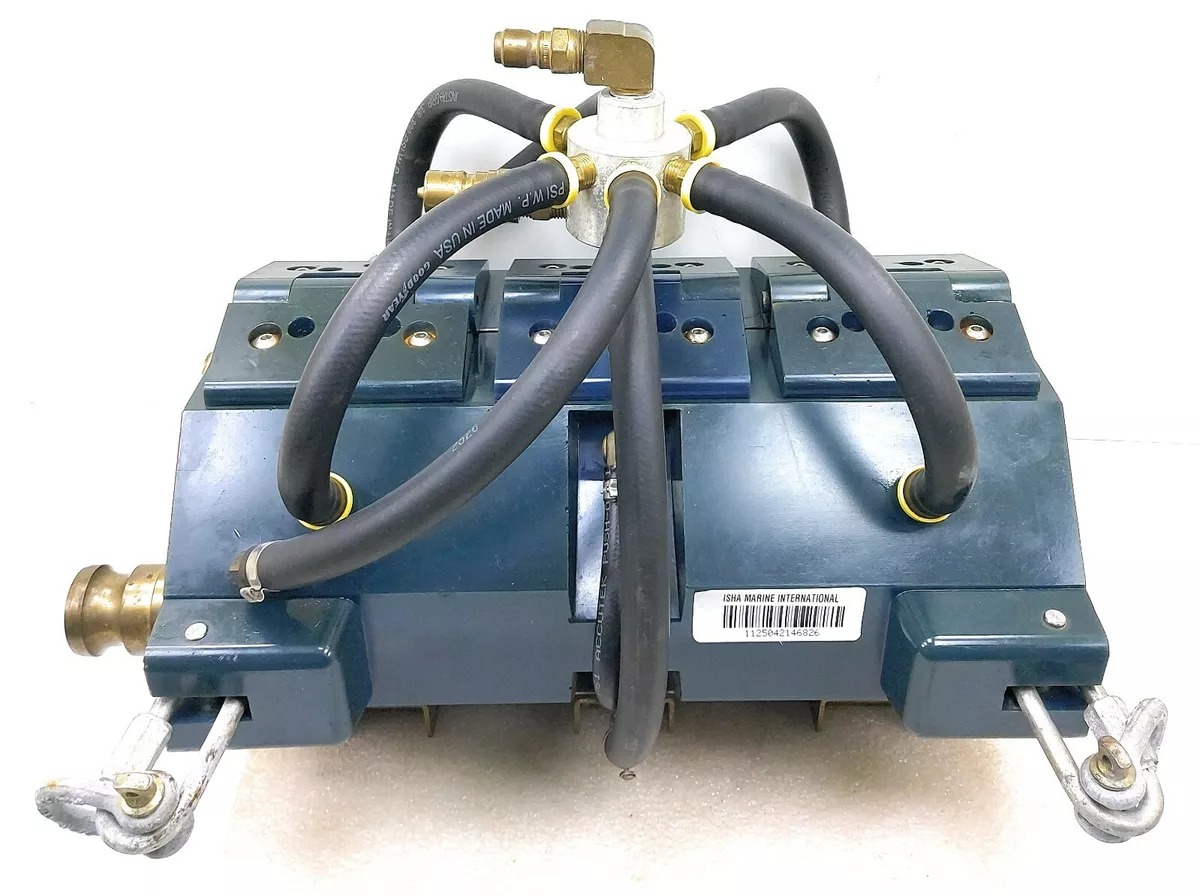

Wire rope lubricators are devices designed to apply an oil-based lubrication system to wire ropes. This process is essential for preventing rust, reducing friction and enhancing the overall endurance. The lubricator is responsible for ensuring that the lubricating ingredients are evenly distributed along the length of wire ropes, guarding them against wear and tear.

What’s the function of cleaners of wires in cable maintenance?

Cleaners for wires and cables are both crucial to ensure clean cables. They are made to eliminate contaminants, debris, and fluids that might build up on the cable during various actions. The use of wire cleaners is particularly important in areas where cables are exposed to extreme conditions, which can result in a decrease in performance, and also preventing damage.

Optimizing Cable Lifespan:

Wire lubricators and wire cleaners when used in conjunction can greatly extend the lifespan of cables. Wire cleaners and lubricators can be used to apply lubrication to the cables and remove the pollutants. This protects the cables from friction, corrosion as well as other external forces. The protection of the cable’s integrity results into a longer operational lifespan and lower costs for maintenance over time.

The efficiency of the application

Wire rope lubricators are designed to be easy to use and efficient in their application. The lubricators can be applied in a range of types and sizes of wire ropes. This allows for flexibility in cable maintenance. The automated and systematic application of lubrication guarantees consistency which eliminates the chance of uneven coverage that manual methods could cause.

Ability to Adapt in a Changing Environment:

In the fields where cables are exposed harsh environments, like those used in construction, drilling or maritime operations the flexibility of wire rope lubricators and wire cleaners is essential. They have been developed to to withstand extreme conditions. They are, therefore, reliable devices for maintaining cables.

Solutions for maintenance that are cost-effective:

An approach that is proactive to maintaining your cable using cables and lubricants, as well as cleaners, is a more cost-effective choice in the long-term. These sophisticated tools are an affordable investment when relative to the cost of repairs, replacements or downtime that result from neglecting maintenance. Know more at Cable Cleaner

Conclusion:

Wire cleaners and lubricators used for wire ropes are the protectors who guarantee the integrity of cables and precision across a wide range of industries. The systematic application of lubrication and the removal of contaminants contribute to the protection of cables, ultimately decreasing maintenance costs and increasing the efficiency of operation. Cables are still used in critical industries, so the use of tools to maintain cables that help maintain reliability and success is crucial.

Efficiency Redefined: The Magic Of Wireline Cleaners In Fluid Removal

How PVPHT Creates High-Stakes PVP Without Pay-To-Win Mechanics

When Botanical Terpenes Reach Their Limit And Cannabis-Derived Options Take Over

Healing Isn’t Linear: Understanding Setbacks In Drug And Alcohol Rehab

Not Just For Games: How Magic Performers Choose Professional Playing Cards

Running A Sportsbook Is A Business Here’s How Successful Bookies Think About It

A Step-By-Step Breakdown Of Professional Pool Opening Services

We have a lot more just for you! Lets join us now

45% Off

Wire cleaners and wire rope lubricators are indispensable in the world of repair and maintenance, where precision is key. These devices are essential for ensuring a smooth and efficient operation of the cable as well as long-lasting life in various industries. Wire cleaners and rope lubricators are essential for maintaining cables. In this piece, we look at their uses, benefits and the positive effects they have on the overall effectiveness.

Understanding Wire Rope Lubricants:

Wire rope lubricators are devices designed to apply an oil-based lubrication system to wire ropes. This process is essential for preventing rust, reducing friction and enhancing the overall endurance. The lubricator is responsible for ensuring that the lubricating ingredients are evenly distributed along the length of wire ropes, guarding them against wear and tear.

What’s the function of cleaners of wires in cable maintenance?

Cleaners for wires and cables are both crucial to ensure clean cables. They are made to eliminate contaminants, debris, and fluids that might build up on the cable during various actions. The use of wire cleaners is particularly important in areas where cables are exposed to extreme conditions, which can result in a decrease in performance, and also preventing damage.

Optimizing Cable Lifespan:

Wire lubricators and wire cleaners when used in conjunction can greatly extend the lifespan of cables. Wire cleaners and lubricators can be used to apply lubrication to the cables and remove the pollutants. This protects the cables from friction, corrosion as well as other external forces. The protection of the cable’s integrity results into a longer operational lifespan and lower costs for maintenance over time.

The efficiency of the application

Wire rope lubricators are designed to be easy to use and efficient in their application. The lubricators can be applied in a range of types and sizes of wire ropes. This allows for flexibility in cable maintenance. The automated and systematic application of lubrication guarantees consistency which eliminates the chance of uneven coverage that manual methods could cause.

Ability to Adapt in a Changing Environment:

In the fields where cables are exposed harsh environments, like those used in construction, drilling or maritime operations the flexibility of wire rope lubricators and wire cleaners is essential. They have been developed to to withstand extreme conditions. They are, therefore, reliable devices for maintaining cables.

Solutions for maintenance that are cost-effective:

An approach that is proactive to maintaining your cable using cables and lubricants, as well as cleaners, is a more cost-effective choice in the long-term. These sophisticated tools are an affordable investment when relative to the cost of repairs, replacements or downtime that result from neglecting maintenance. Know more at Cable Cleaner

Conclusion:

Wire cleaners and lubricators used for wire ropes are the protectors who guarantee the integrity of cables and precision across a wide range of industries. The systematic application of lubrication and the removal of contaminants contribute to the protection of cables, ultimately decreasing maintenance costs and increasing the efficiency of operation. Cables are still used in critical industries, so the use of tools to maintain cables that help maintain reliability and success is crucial.